Despite these disadvantages, we believe vertical axis wind turbines are still worth investing in and developing. It is certain that this type of wind turbine has the potential to not only establish its niche market, but also provides alternatives to horizontal axis models where they do not fit.

5 Disadvantages of vertical wind turbines

Vertical axis wind turbines have 7 key advantages that make them perfect for small-scale power generation in unstable windy regions and urban areas. However, they have a few disadvantages as well. In fact, the design of this type of turbine remains popular as engineers come to tackle the challenges.

Through 5 years of research and development, we have also come across and addressed certain problems and improvements of vertical axis wind turbines.

The challenges brought by disadvantages of vertical axis wind turbines

1. Less Rotation Efficiency

Vertical axis wind turbines often have less rotation efficiency. This is part of the reason why vertical axis wind turbines have lower efficiency.

Due to the rotor design, not all the blades on the vertical axis rotor receive incoming wind at the same time. In fact, only the wind-facing blades are driven by the wind to turn while the others are simply following along. During rotation, vertical axis rotors are also faced with more drag— or aerodynamic resistance— on the blades.

This is especially shown on Savonius wind turbines because they have wider blade surfaces.

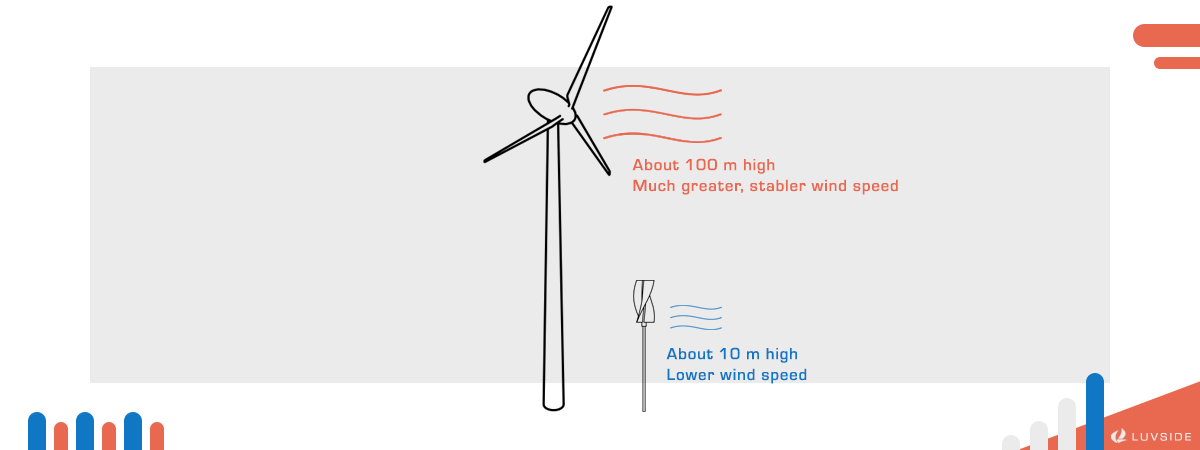

2. Lower Available Wind Speed

Since vertical axis wind turbines are typically installed on ground level, they do not harness higher wind speeds often found at higher levels. Consequently, less wind energy is available for ground-level vertical axis wind turbines. A common solution to this is to install the turbine on the rooftop of a building.

To address this problem, we have improved the rotor design so that it can be mounted on top of a mast. The rotor and the mast combined tower our vertical axis wind turbine to 10 meter high, with the generator and power electronics located at the 4-meter height.

3. Component Wear-down

Often placed on ground level and populated environments, vertical axis wind turbines face more turbulence and issues of vibrations. When in operation, not only do the blades need to withstand more force, the bearing between the rotor and the mast also needs to endure higher pressure. In earlier models, it was more likely for the blades to bend or crack. For others, this can result in more maintenance and therefore more cost.

To strengthen our own turbines, we have taken wear-down calculations into consideration for design and manufacture. The LuvSide vertical axis wind turbines are now robust enough to stand wind speed equivalent to a strong tropical storm.

4. Less Efficiency

Vertical axis wind turbines are known to have less efficiency compared to horizontal axis wind turbines. This is mainly due to the nature of their design and operational characteristics.

On average, the efficiency of a horizontal axis wind turbine lays between 40 to 50 %, meaning the turbine is able to convert 40% to 50 % of the kinetic energy it receives into actual electrical power. On the other hand, a Savonius vertical axis wind turbine has an average efficiency of 10 to 17 %, while the Darrieus vertical axis wind turbine reaches 30 to 40 %.

Even so, given the suitable environment, a Savonius wind turbine can still produce enough power to support annual consumption of a normal two-person household.

5. Self-Starting Mechanism

While horizontal axis wind turbines and Savonius wind turbines start turning automatically once receiving wind, Darrieus wind turbines often rely on a starting mechanism. This is because the wing design of Darrieus wind turbines does not always guide the wind to form enough torque for rotation. At the moment, this is still a challenge that many, including us, are trying to tackle.